Lefatšeng la kajeno le potlakileng, theknoloji e bapala karolo ea bohlokoa liindastering tse fapaneng 'me e' ngoe ea mahlale a fetotseng ts'ebetso ea tlhahiso ke mochini oa CNC.

Kgutsufatso CNC (Computer Numerical Control) ke thekenoloji e tsoetseng pele e sebelisang software ea k'homphieutha ho laola motsamao oa mochine. Leha machining a CNC a sebelisoa mafapheng a mangata, bohlokoa ba ona indastering ea bongaka bo ntse bo hola haholo.

Sengoliloeng sena se shebisisa ka botebo litšebeliso tse fapaneng tsa theknoloji ea machining ea CNC indastering ea bongaka, e shebane le phello ea eona ho nepahala, ho itlhophisa, le liphetho tsa mokuli.

CNC machining ke ts'ebetso ea ho sebelisa mechini e laoloang ke komporo ho bopa lisebelisoa tse tala le ho etsa likarolo. Pelo ea mochini oa CNC ke sistimi ea taolo ea komporo e tsamaisang hantle motsamao oa lisebelisoa le lisebelisoa.

Likarolo tsa bohlokoa tsa mechini ea CNC li kenyelletsa likarolo tsa taolo ea likhomphutha, li-motor, li-drive le lisebelisoa tsa ho itšeha. Ka letoto la litaelo tse hlophisitsoeng, mechine e ka etsa mesebetsi e rarahaneng le e nepahetseng ntle le ho kenella ho fokolang ha motho.

CNC machining e fana ka melemo e mengata ho feta mekhoa ea setso ea tlhahiso. E meng ea melemo e metle:

Indasteri ea bongaka e na le litlhoko tse ikhethang le mathata ha ho tluoa tabeng ea ho etsa lisebelisoa le lisebelisoa. Ho latela litsebi tsa CNC ho Artmachining, li ka thusa indasteri ea bongaka ho fumana litholoana tse ntle ka lits'ebetso tsa machining tsa CNC.

Ho nepahala, ho nepahala le ho tšepahala ke lintlha tsa bohlokoa tlhahisong ea lisebelisoa tsa bongaka, esita le phoso e nyenyane e ka ba le liphello tse tebileng. Mona ke moo machining a CNC a fetolang papali. Bokhoni ba theknoloji ena ea ho fumana mamello e tiileng le ho nepahala ho phahameng ho etsa hore e be ea bohlokoa haholo lits'ebetsong tsa bongaka.

Mechine ea CNC e kenya letsoho haholo ho ntlafatsa sephetho le polokeho ea mokuli. Ho sebelisoa software e tsoetseng pele le lisebelisoa tsa morao-rao, lisebelisoa tsa bongaka li ka etsoa ka mokhoa o nepahetseng haholo, ho netefatsa hore li lekana hantle, li tsamaisana hantle le ho sebetsa hantle.

Ho tšepahala ha machining a CNC ho fokotsa kotsi ea liphoso, ho lumella mekhoa e sireletsehileng ea bongaka le tlhokomelo e ntlafetseng ea bakuli.

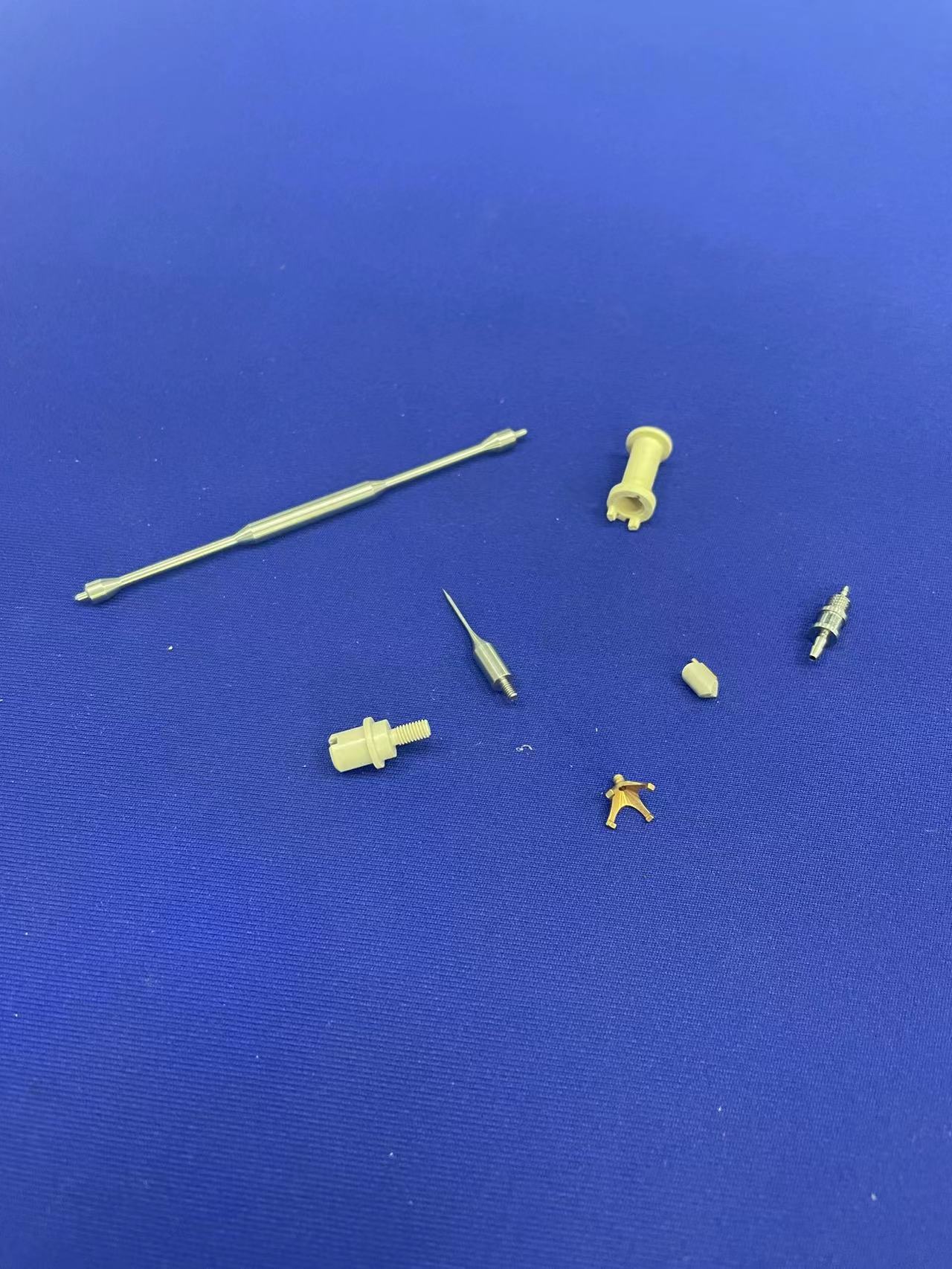

CNC machining e sebelisoa haholo likarolong tsohle tsa tlhahiso ea lisebelisoa tsa bongaka. Ha re shebeng lisebelisoa tse ling tsa bohlokoa. Ho ea ka litsebi tsa k'hamphani ea Chaena cncfirst.com, boholo ba likopo tsena ke merero e laetsoeng ke indasteri ea bongaka.

Li-implants tsa masapo tse kang ho nkeloa sebaka ke letheka le mangole li rua molemo haholo ho tsoa ho theknoloji ea machining ea CNC.

Ts'ebetso ea tlhahiso e kenyelletsa ts'ebeliso ea mechini ea CNC ho theha le ho qaqisa li-implants ho ea ka litlhaloso tse hlakileng. CNC machining e lumella li-implants hore li etsoe ka mokhoa o ikhethileng le ho etsoa motho ka mong ho lumellana le litlhoko tsa mokuli.

Theknoloji e boetse e fana ka khetho e pharaletseng ea thepa, e lumellang bahlahisi ho khetha thepa e nang le matla a lekaneng, ho tšoarella le ho lumellana ha lintho.

CNC machining e phetha karolo ea bohlokoa tlhahisong ea lisebelisoa tsa boleng bo holimo tsa ho buoa. Theknoloji ena e etsa hore ho khonehe ho hlahisa lisebelisoa tsa meralo e rarahaneng le li-geometri tse rarahaneng.

Mechini ena e khona ho seha likarolo tse ntle ka nepo, ho fella ka lisebelisoa tse nang le ts'ebetso le ts'ebetso e phahameng. Tšebeliso ea mechine ea CNC e tiisa ho tsitsa ha tlhahiso ea lisebelisoa tsa ho buoa, tse bohlokoa ho boloka tlhahiso le ho fumaneha ha tsona ka nako e telele.

Ho feta moo, machining a CNC a thusa ho amohela litlhoko tsa sterilization e le hore lisebelisoa li ka sebelisoa ka mokhoa o sireletsehileng lits'ebetsong tsa bongaka.

Mechine ea CNC e fetotse lefats'e la li-prosthetics le orthotics, e fana ka melemo e mengata ea ho itloaetsa le ho nepahala. Ho sebelisa theknoloji ea CNC, lisebelisoa tsa maiketsetso le li-orthotic li ka etsoa hore li lumellane le sebōpeho se ikhethang sa motho.

Mechini ea CNC e ka khaola ka nepo libopeho le li-contours tse rarahaneng, ea hlahisa lisebelisoa tse bonolo, tse bobebe, le ergonomic. Bokhoni ba ho etsa lihlahisoa tsa maiketsetso le lihlahisoa tsa masapo li ntlafatsa boiketlo ba mokuli, ho tsamaea le boleng ba bophelo.

Mokhoa oa ho laola lipalo oa k'homphieutha o phetha karolo ea bohlokoa tlhahisong ea likarolo tsa bohlokoa tsa lisebelisoa tsa bongaka. Likarolo tse kang li-valve, li-connectors le lipompo li hloka ho nepahala ho phahameng le ho nepahala ho lekaneng ho netefatsa ts'ebetso e nepahetseng.

Mechini ea CNC e ka hlahisa likarolo tsena ka mokhoa o ikhethileng, ho fihlela litlhoko tse thata tsa indasteri ea bongaka. Ntle le moo, machining a CNC a thusa ho potlakisa prototyping le ntlafatso ea moralo, e lumellang baetsi ho ntlafatsa lihlahisoa tsa bona le ho li tlisa 'marakeng ka katleho.

Lefatše la machining a CNC le ntse le hola, ka likhatelopele tse ling tse lebisitseng indasteri ea bongaka. Mohlala, kopanyo e kholo ea li-automation le liroboto lits'ebetsong tsa machining tsa CNC.

Automation e ka potlakisa tlhahiso, ea fokotsa liphoso le ho eketsa tlhahiso. Sistimi ea liroboto e ka etsa mesebetsi e rarahaneng ka nepo, ea eketsa ts'ebetso ea mochini oa CNC ho etsa lisebelisoa tsa bongaka.

Ho feta moo, tsoelo-pele ea lisebelisoa tsa software le tsa papiso e etsa hore ho be bonolo ho rala le ho ntlafatsa likarolo tsa bongaka pele ho etsoa, ho boloka nako le lisebelisoa.

Ho kopanya mahlale a tlatsetso a tlhahiso joalo ka khatiso ea 3D ka mochini oa CNC ho boetse ho bula menyetla e mecha. Motsoako ona o u lumella ho etsa mehaho e rarahaneng le ho kopanya lisebelisoa tse 'maloa ho sesebelisoa se le seng. Bokhoni ba ho hlahisa lisebelisoa tsa bongaka tse rarahaneng le tse ikhethileng ka mekhoa ea tlhahiso e nyalisitsoeng e fana ka menyetla e mengata ea bokamoso ba tlhokomelo ea bophelo bo botle.

Leha machining a CNC a tlisa melemo e mengata tlhahisong ea lisebelisoa tsa bongaka, ho na le liphephetso le lintlha tse ling tse lokelang ho tsotelloa.

Ntlha ea bohlokoa ke litlhoko tsa taolo le litekanyetso tsa taolo ea boleng tse laolang tlhahiso ea lisebelisoa tsa bongaka. Ho latela melaoana e kang Melao ea Tsamaiso ea Boleng ea FDA (QSR) ho bohlokoa ho netefatsa polokeho le katleho ea lisebelisoa tsa bongaka.

Basebetsi ba nang le litsebo le litsebi ke ntlha e 'ngoe ea bohlokoa ho kenngoeng tšebetsong ka katleho ha mochini oa CNC indastering ea bongaka. Theknoloji ena e hloka litsebi tse koetlisitsoeng tse ka khonang ho hlophisa, ho sebetsa le ho boloka mechine ea CNC. Matsete a lekaneng thutong le koetlisong ea basebetsi ba mochini oa CNC e bohlokoa ho holisa bokhoni ba bona indastering ea tlhokomelo ea bophelo.

Ho bohlokoa hape ho hlokomela mefokolo le mefokolo ea mochini oa CNC indastering ea bongaka. Lisebelisoa tse ling tse rarahaneng tsa bongaka kapa likarolo li ka hloka ts'ebetso e eketsehileng ea tlhahiso kapa ts'ebetso ea morao-rao e ke keng ea finyelloa ka mochini oa CNC feela. Baetsi ba lokela ho lekola ho khoneha le ho lumellana ha mochini oa CNC bakeng sa lits'ebetso tse ikhethileng ho netefatsa liphetho tse nepahetseng.

Ha mochini oa CNC o ntse o tsoela pele ho laola indasteri ea bongaka, ho bohlokoa ho hlahloba melemo ea ho tlisa lits'ebeletso tsa mochini oa CNC ho tsoa linaheng tse kang China tse nang le boiphihlelo lefapheng lena.

China esale e nkuoa e le setsi sa lefats'e sa tlhahiso, se fanang ka litheko tsa tlholisano bakeng sa lits'ebeletso tsa machining tsa CNC. Litsenyehelo tse tlase tsa basebetsi le tsa ts'ebetso naheng ea China li boloka chelete bakeng sa lik'hamphani tse kenyang likarolo tsa mochini oa CNC. Ho feta moo, ho ba teng ha marang-rang a mangata a bafani le bahlahisi ba Chaena ho etsa hore tlhōlisano e be bohale, ho fokotsa litheko ntle le ho senya boleng.

China e tsetetse haholo ntlafatsong ea mahlale le nts'etsopele ea meralo ea motheo, e e etsa moetapele oa machining oa CNC. Baetsi ba Machaena ka tloaelo ba na le mechini ea morao-rao ea CNC le lisebelisoa ho netefatsa ho nepahala ho phahameng, ho nepahala le ho sebetsa hantle ha tlhahiso. Ka ho kenya lits'ebeletso tsa machining tsa CNC ho tsoa Chaena, likhoebo li ka fumana phihlello ea theknoloji e tsoetseng pele le ho rua molemo ho tsoa ho boitseanape ba litsebi tse nang le boiphihlelo tšimong.

China e na le bokhoni bo tsotehang ba ho etsa lihlahisoa 'me e khona ho sebetsana le liodara tse kholo ka katleho le kapele. Ebang ke lisebelisoa tse phahameng tsa lisebelisoa tsa bongaka kapa li-implants tse rarahaneng tsa masapo, litšebeletso tsa machining tsa CNC Chaena li ka finyella litlhoko tsa tlhahiso ea liindasteri tse sa tšoaneng tsa bongaka. Bokhoni ba ho phahamisa tlhahiso kapele le ho fihlela linako tse behiloeng ke monyetla o moholo bakeng sa likhoebo tsa tlhokomelo ea bophelo bo botle.

Likhamphani tsa machining tsa CNC tsa China li utloisisa bohlokoa ba ho boloka litekanyetso tsa taolo ea boleng le ho latela melao. Bahlahisi ba tsebahalang naheng ea China ba thehile litsamaiso tsa taolo ea boleng ho etsa bonnete ba hore likarolo tse hlahisoang li fihlela litlhoko tse hlokahalang le ho ba le taolo e thata ea boleng. Ka ho kenya lits'ebeletso tsa mochini oa CNC ho tsoa Chaena, likhoebo li ka phomola habonolo ha li tseba hore li fumana lihlahisoa tsa boleng bo holimo tse fihlelang litekanyetso le melaoana ea indasteri.

Litšebeletso tsa machining tsa CNC naheng ea China li fana ka maemo a holimo a ho itloaetsa le ho feto-fetoha le maemo ho fihlela litlhoko tse ikhethang tsa bareki. Ka software e tsoetseng pele le basebetsi ba mahlale ba nang le boiphihlelo, bahlahisi ba Machaena ba ka fumana meralo e rarahaneng, litlhaloso tse ikhethang le litharollo tse ikhethileng. Ho feto-fetoha ha maemo ho lumella ho theha likarolo tsa bongaka tse ikhethileng, lisebelisoa le lisebelisoa ho fihlela litlhoko tse khethehileng tsa litsebi tsa tlhokomelo ea bophelo le bakuli.

Khokahano e pharalletseng ea phepelo ea China e netefatsa ts'ebetso e ntlafalitsoeng le e sebetsang bakeng sa lits'ebeletso tsa machining tsa CNC tse tsoang kantle ho naha. Ho tloha ho thepa e tala ho ea ho tlhahiso, taolo ea boleng le lipalangoang, bahlahisi ba Chaena ba na le tsamaiso e feletseng ea tsamaiso ea phepelo. Sena se tiisa hore thepa e tsamaisoa hantle le ho tsamaisoa ka nako ea likarolo tsa mochini oa CNC, ho fokotsa tieho le litšitiso tlhahisong le kabong ea lisebelisoa tsa bongaka.

Likhamphani tsa machining tsa China CNC li tsebahala ka boikemisetso ba tsona ba ho sebelisana le ho buisana ka katleho le bareki ba machabeng. Ka basebetsi ba lipuo tse ngata le mecha ea puisano e sebetsang hantle, lik'hamphani tse kenyang lits'ebeletso tsa mochini oa CNC ho tsoa Chaena li ka buisana habonolo litlhoko tsa tsona, tsa rarolla mathata, le ho boloka likamano tse ntle tsa ts'ebetso le balekane ba tsona ba Machaena. Tšebelisano e sebetsang le puisano li bohlokoa katlehong ea ho fana ka litšebeletso tsa mochini oa CNC.

Theknoloji ea mochini oa CNC e fetotse sebopeho sa tlhahiso ea lisebelisoa tsa bongaka mme e fetotse ka botlalo tsela eo lisebelisoa tsa bongaka li etsoang ka eona. Ho nepahala ha eona, ho itloaetsa, le tlatsetso ea ho ntlafatsa liphetho tsa mokuli li e etsa sesebelisoa sa bohlokoa indastering ea tlhokomelo ea bophelo.

Ho tloha ho li-implants tsa masapo ho ea ho lisebelisoa tsa ho buoa, ho tloha ho li-prosthetics ho ea ho likarolo tsa bohlokoa, machining a CNC a phetha karolo ea bohlokoa ho ntlafatsa boleng, botšepehi le polokeho ea lisebelisoa tsa bongaka.

Ha theknoloji e ntse e tsoela pele ho fetoha le bokhoni bo bocha bo hlaha, machining a CNC a ikemiselitse ho theha bokamoso ba tlhokomelo ea bophelo bo botle. Ka ho kopanya li-automation, liroboto le tlhahiso ea tlatsetso, theknoloji ena e tla ntlafatsa lits'ebetso, ho fokotsa litšenyehelo le ho etsa hore ho thehoe litharollo tse ncha tsa bongaka.

Ena ke nako e monate bakeng sa machining a CNC indastering ea bongaka, 'me tlhahlobo e tsoelang pele ea bokhoni ba eona ntle le pelaelo e tla lebisa tsoelo-peleng e kholo e tla ba le phello e ntle bophelong ba bakuli.

Litaba tsa Robotics le Automation li thehiloe ka Mots'eanong 2015 mme hajoale ke se seng sa libaka tse baloang haholo sehlopheng sa eona.

Ka kopo, nahana ka ho re tšehetsa ka ho ba ba ngolisitseng ba lefang, ka papatso le tšehetso, ho reka lihlahisoa le lits'ebeletso ka lebenkele la rona, kapa motsoako oa tsohle tse ka holimo.

Nako ea poso: Apr-24-2024